Papers

2024

2023

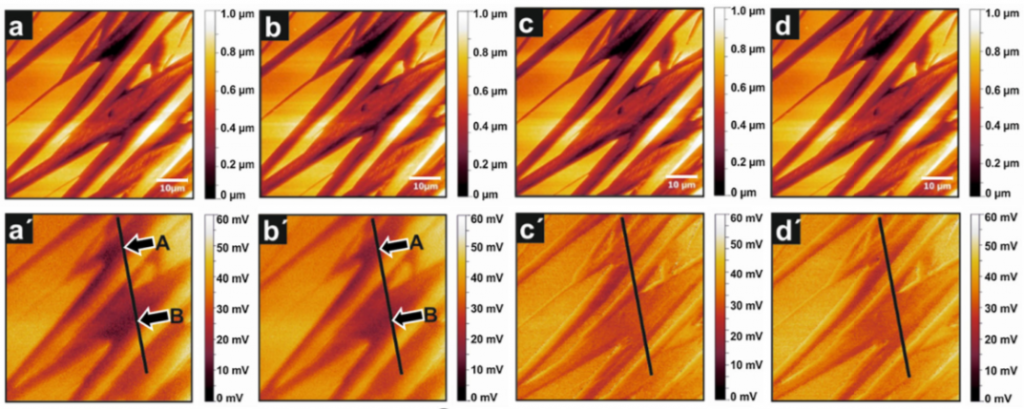

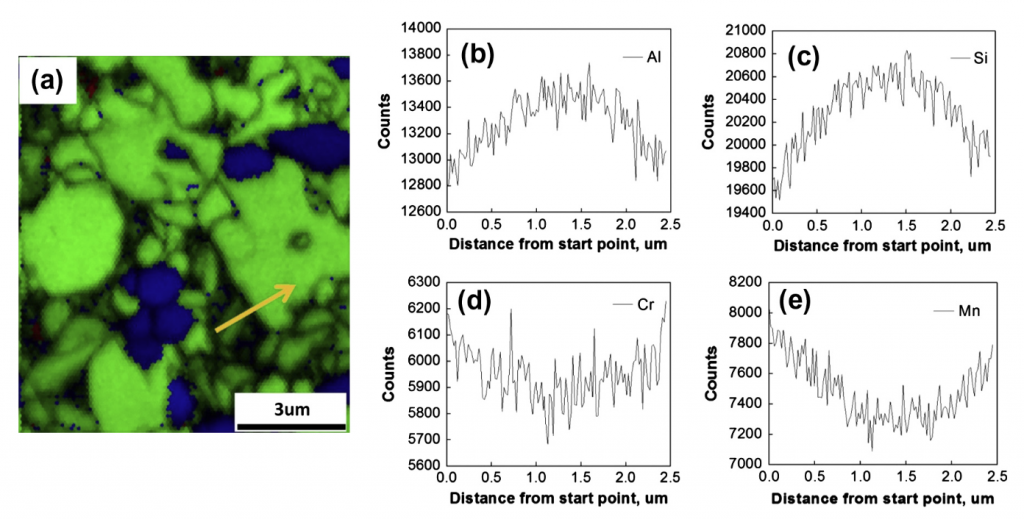

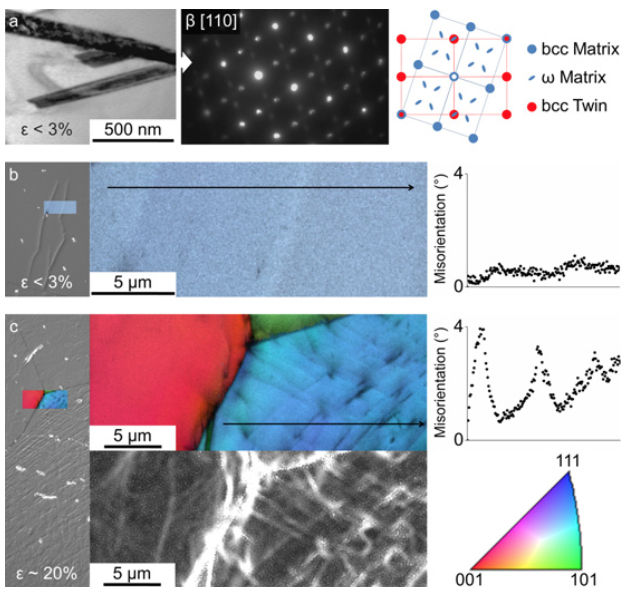

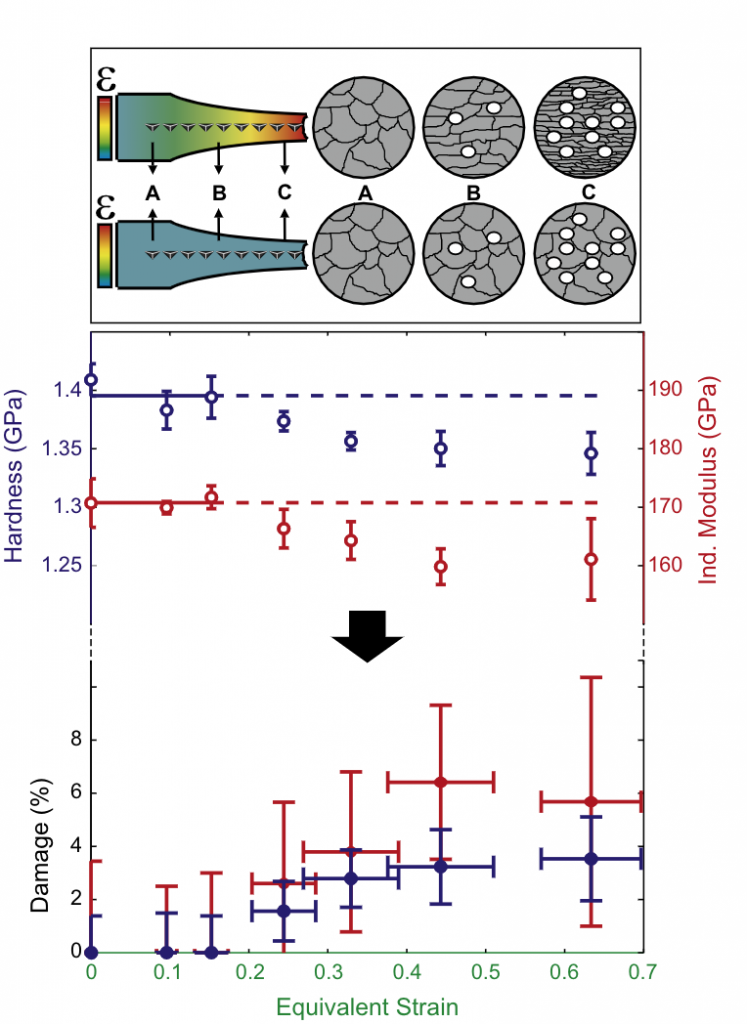

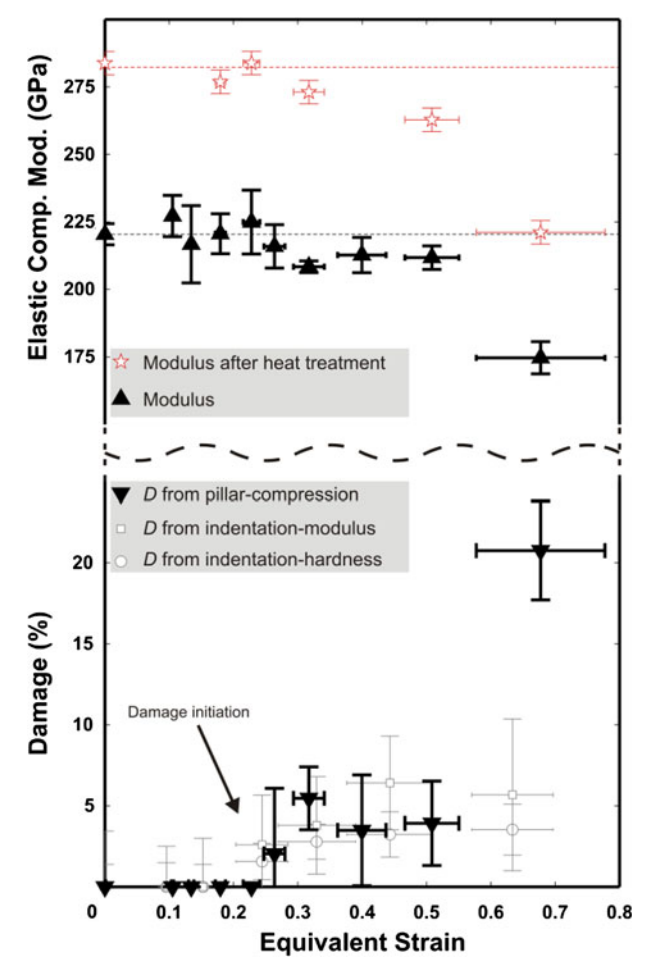

Detecting thermally-induced spinodal decomposition with picosecond ultrasonics in cast austenitic stainless steels

S. Al Dajani, B. R. Dacus, C. A. Dennett, M. G.Burke, L. Waldron, T. S. Byun, J. J. Wall, K. Anglin, O. A. Al Dajani; K. J. Krakowiak, F.-J. Ulm, A. Schwartzmann, C.C. Taşan, P. Hosemann, M. P. Short

Acta Materialia, 246 (2023) 118552

2022

2021

2020

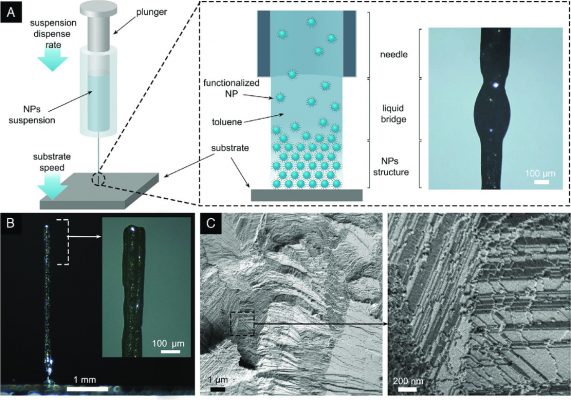

Strong macroscale supercrystalline structures by 3D printing combined with self-assembly of ceramic functionalized nanoparticles

B. Domènech, A. Tan, H. Jelitto, E.Z. Berodt, M. Blankenburg, O. Focke, J. Cann, C.C. Taşan, L.C. Ciacchi, M. Müller, K.P. Furlan, A.J. Hart, G. A. Schneider

Advanced Engineering Materials 22 (2020) 2000352

2019

2018

2017

2016

2015

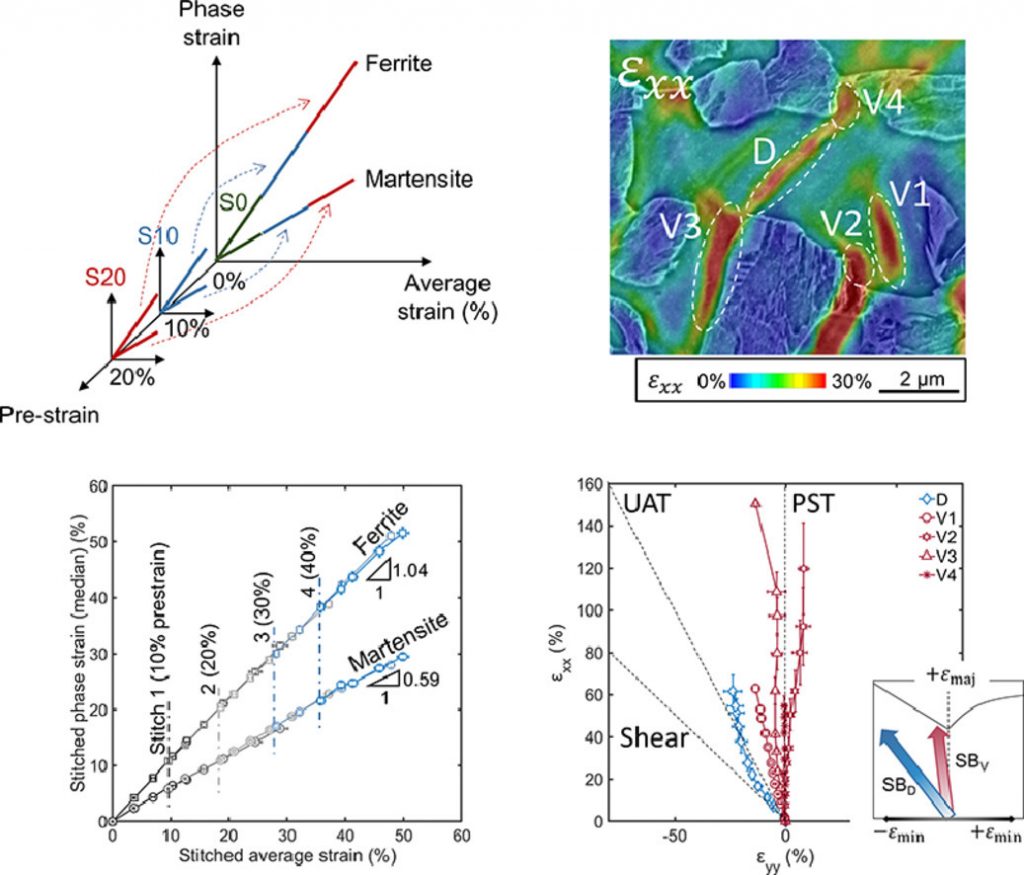

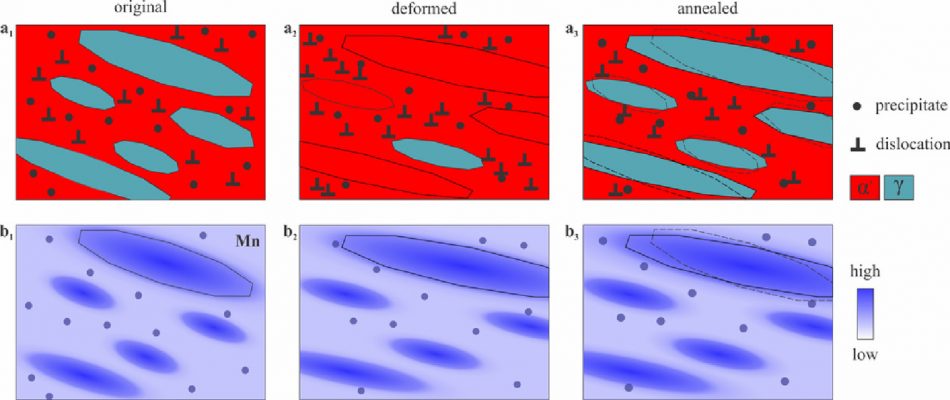

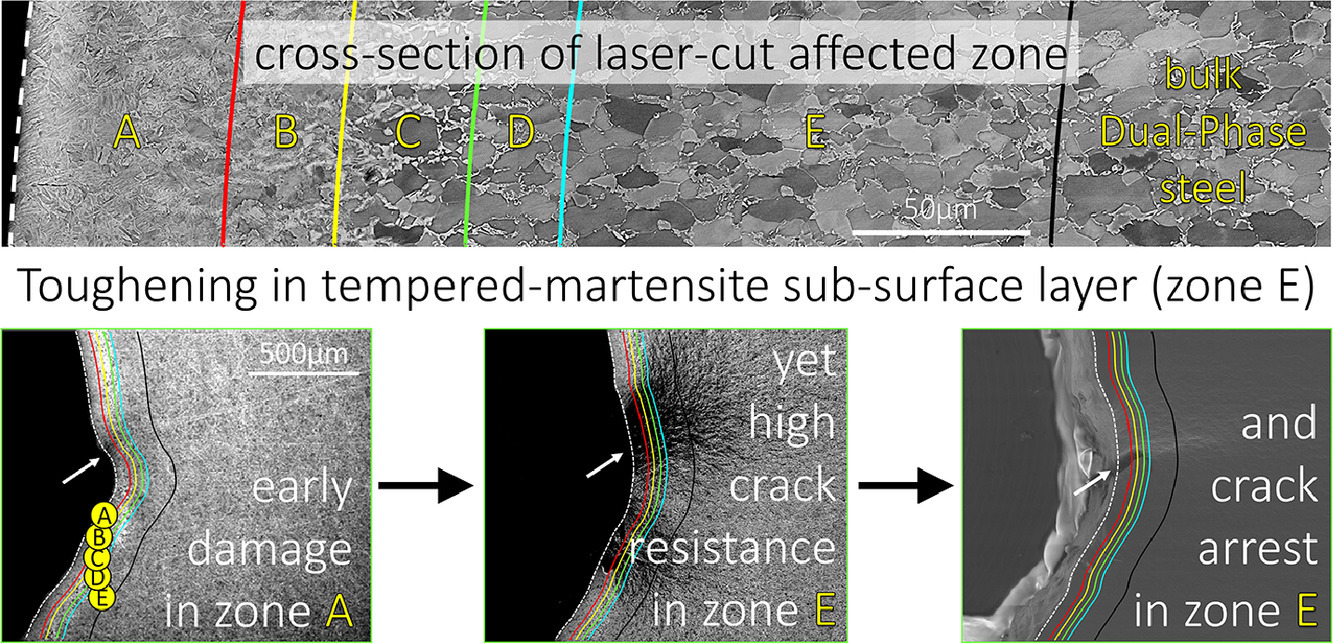

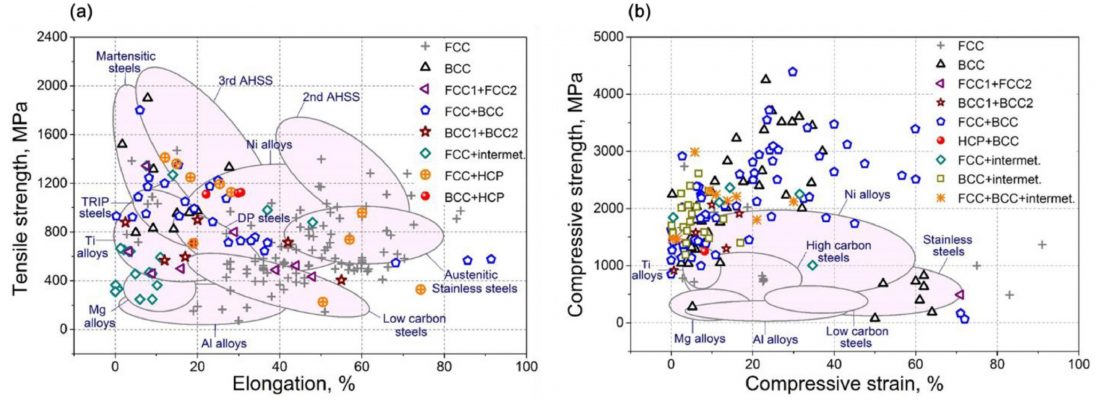

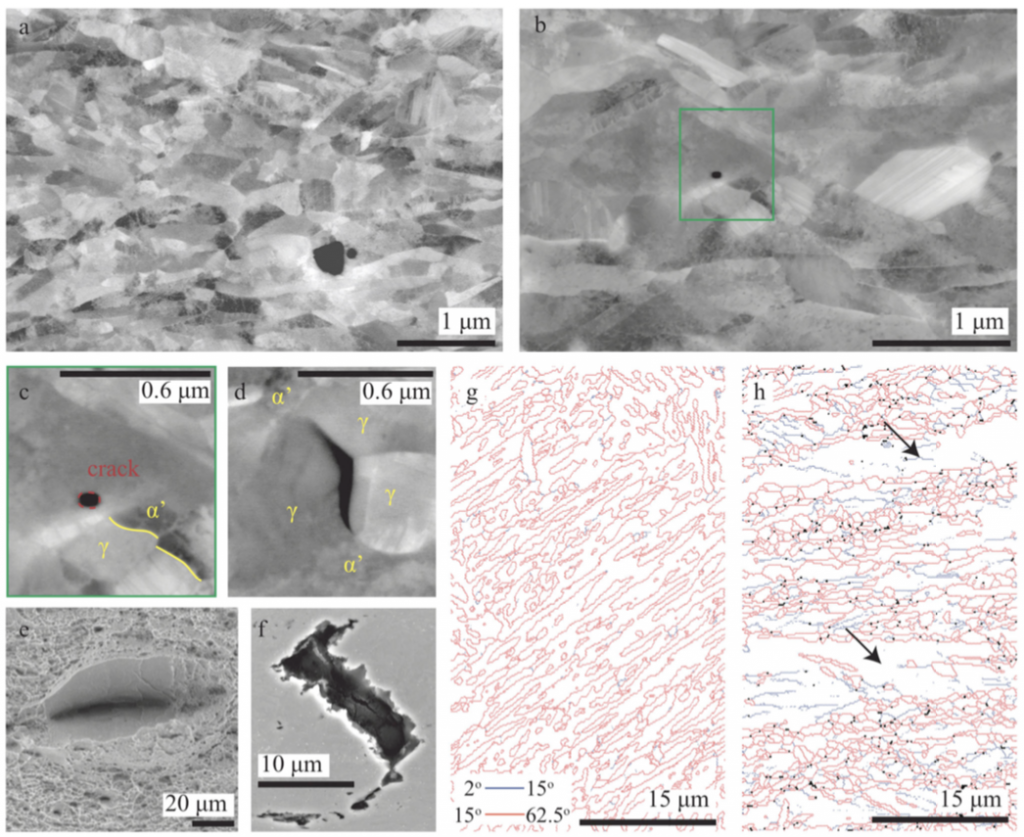

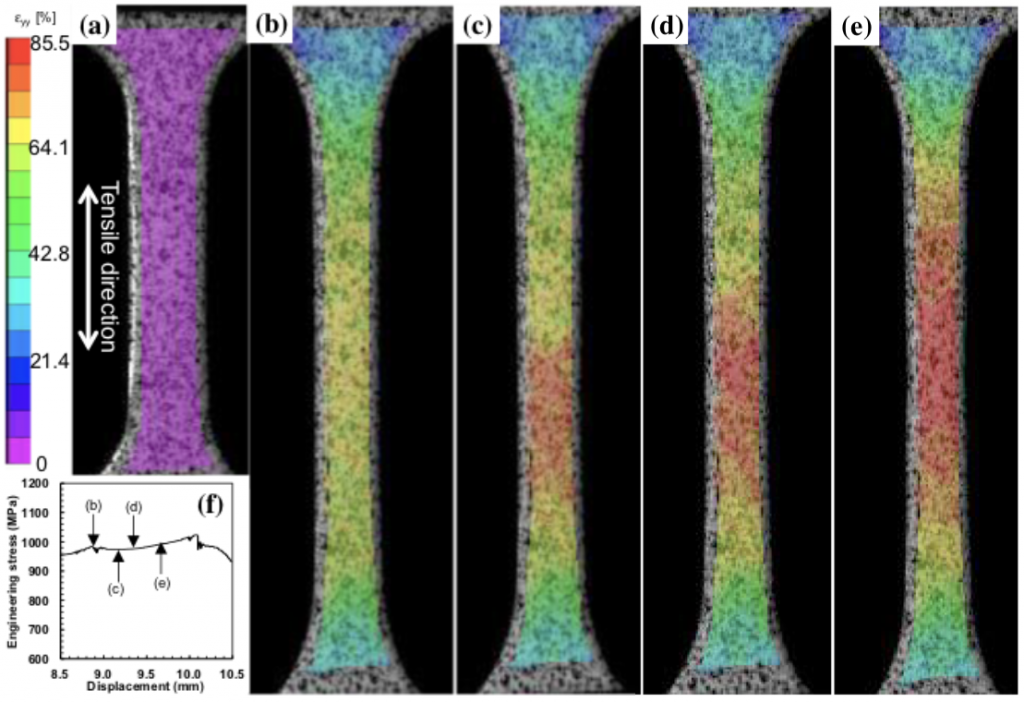

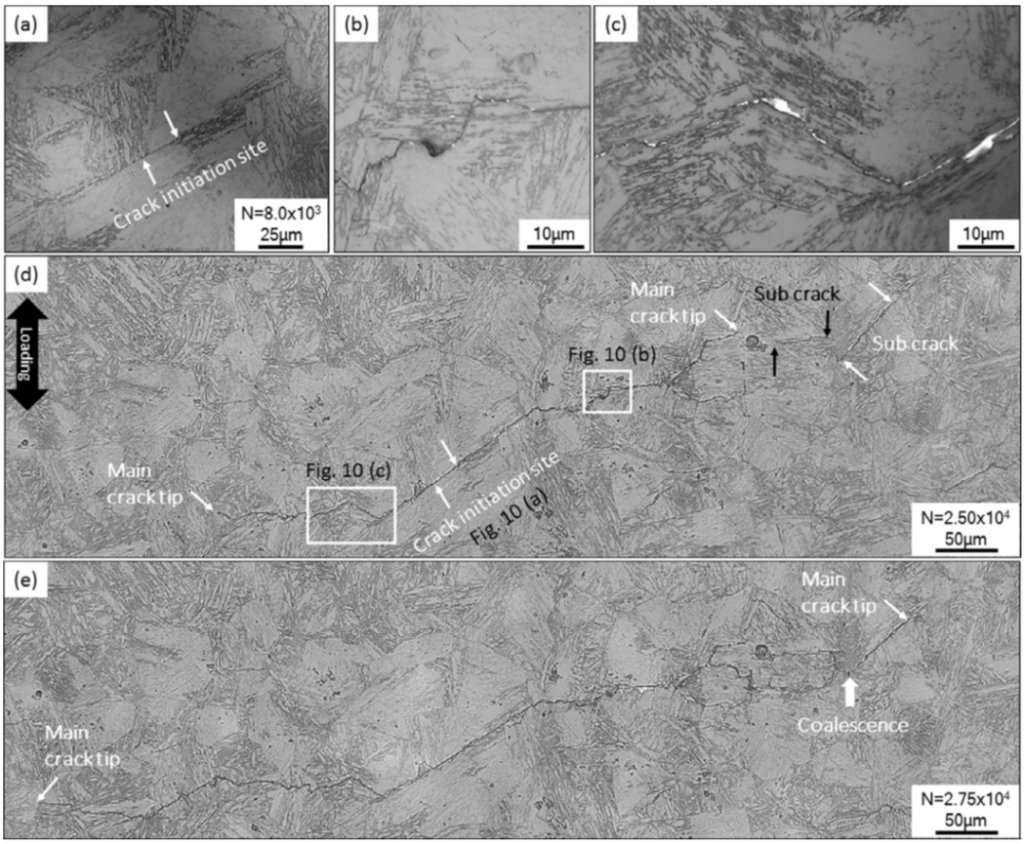

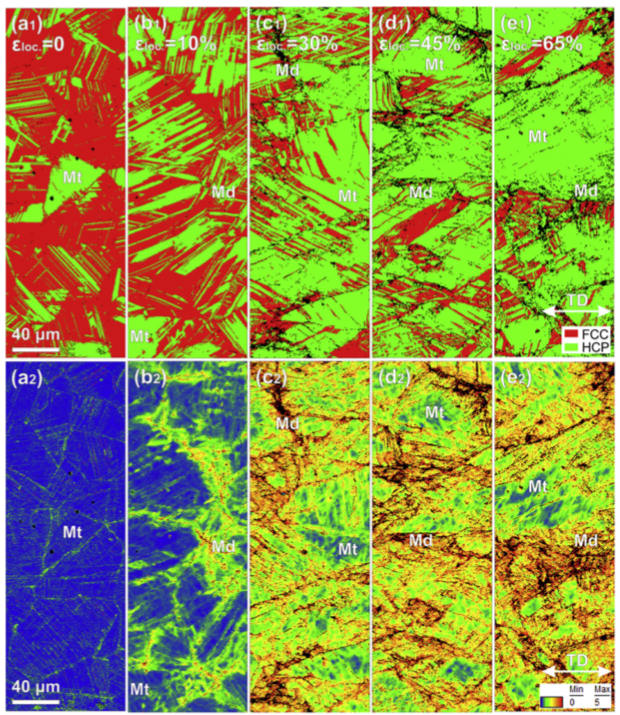

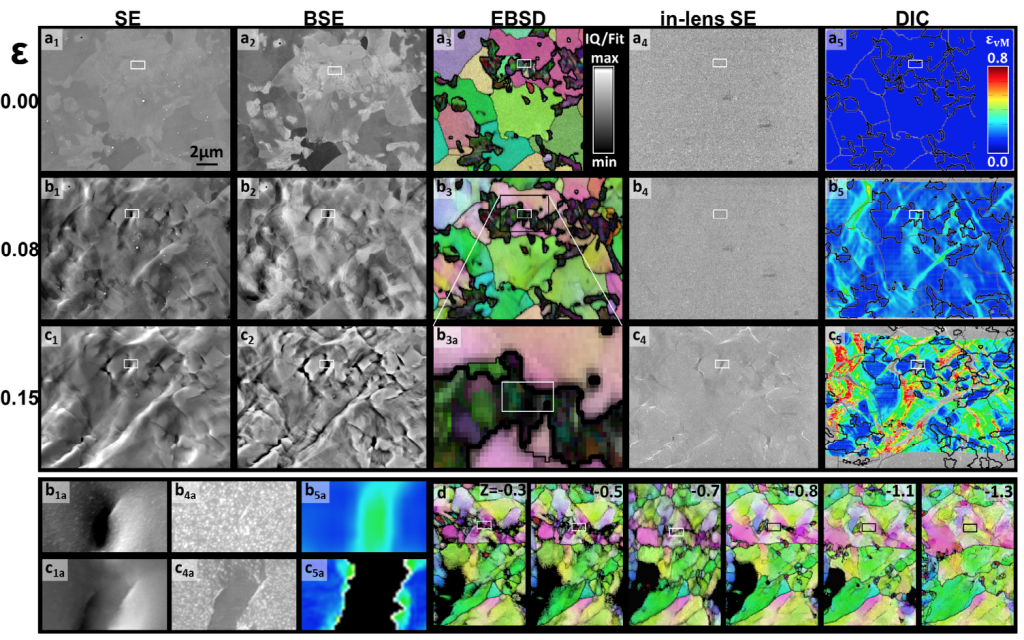

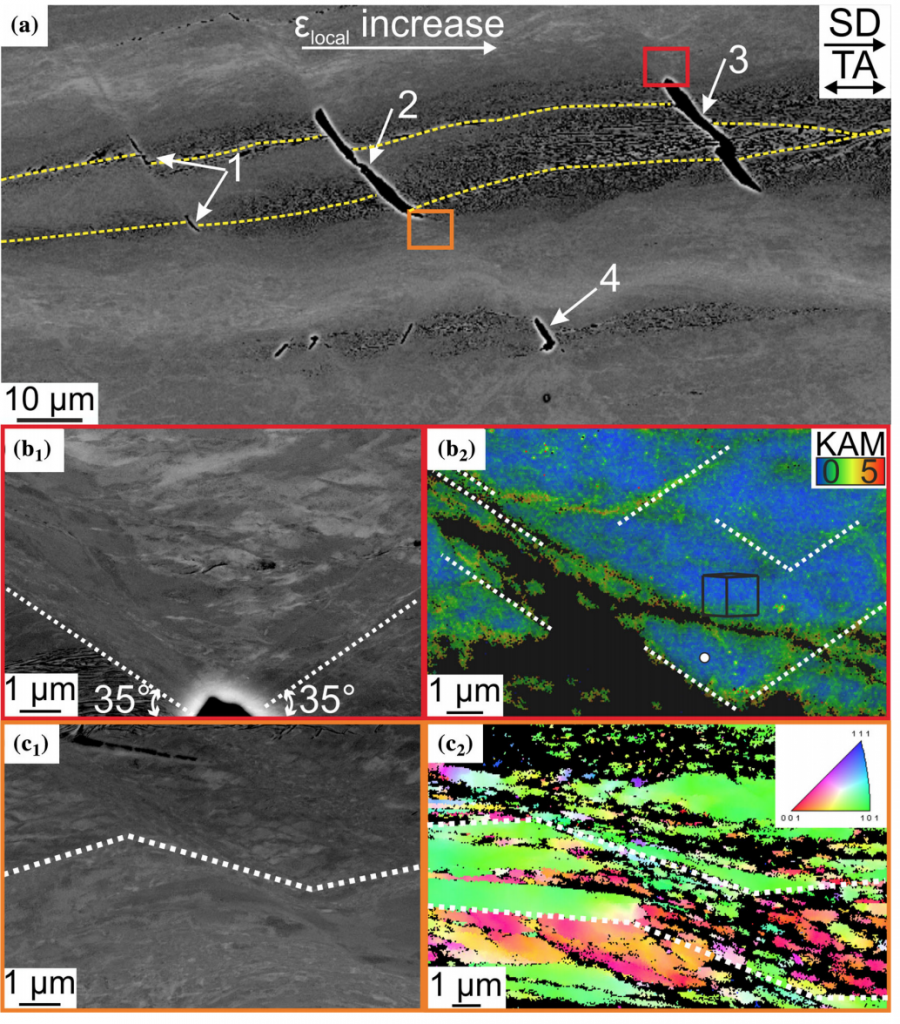

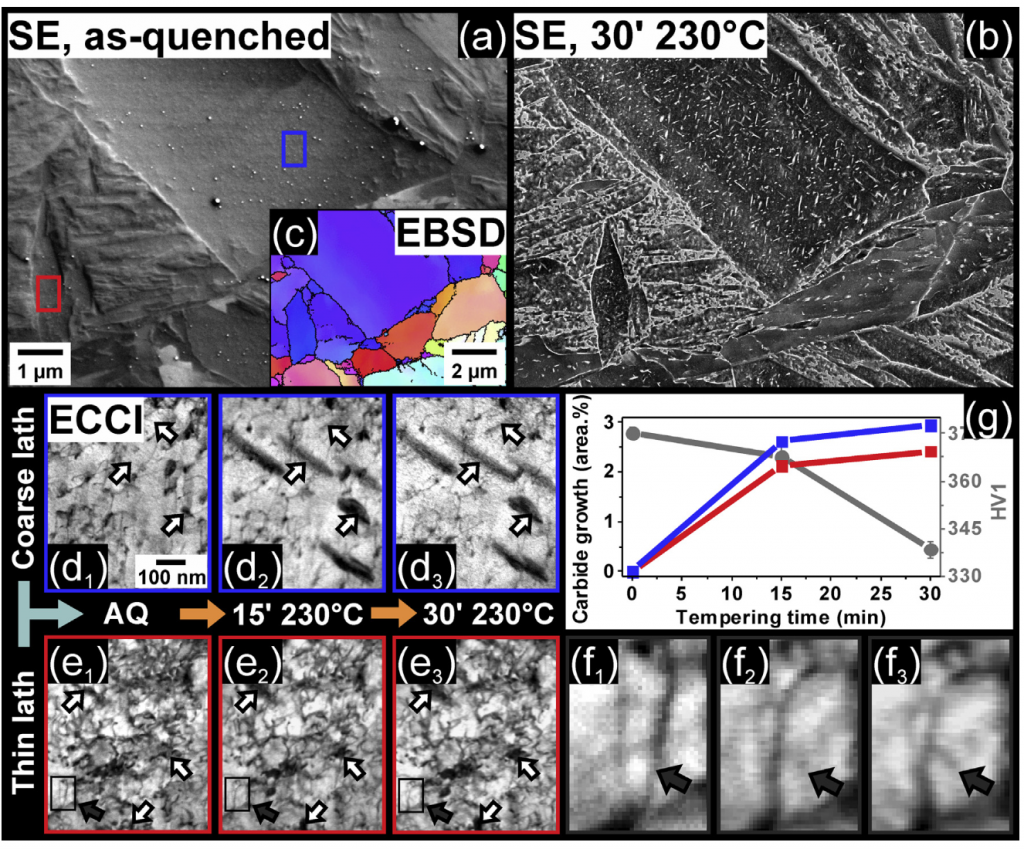

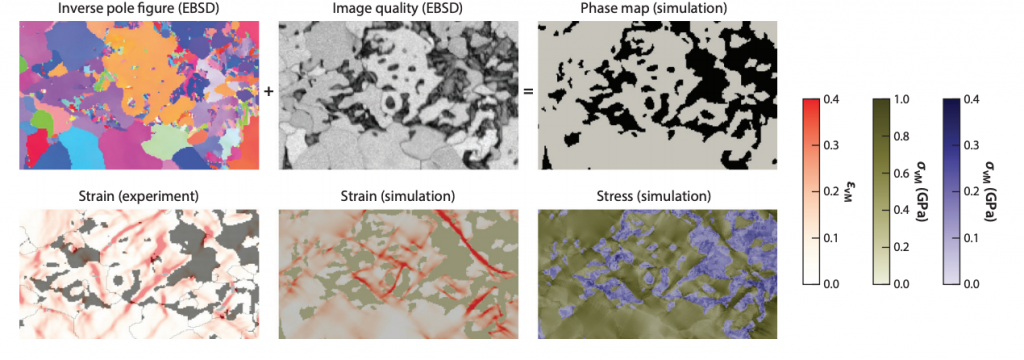

An overview of dual phase steels: Advances in microstructure-oriented processing and micromechanically-guided design

C.C. Taşan, M. Diehl, D. Yan, M. Bechtold, F. Roters, L. Schemmann, C. Zheng, N. Peranio, D. Ponge, M. Koyama, K. Tsuzaki, D. Raabe

Annual Review of Materials Research, 45 (2015) 19.1-19.41.